This weekend we had the pleasure of attending a cane syrup boil with Marcus Stewart, a local syruper.

You can see the documentary here, as we follow the cane syrup making process step by step:

How to Make Cane Syrup

The process of making cane syrup has a few hitches that are difficult to overcome on a home scale. Last time we made our own at home, I had to bypass the juicing process and simply cook the sugar out of the canes. Juicing sugar cane is much better, however, and has a higher yield for much less processing time. If you can juice it!

Juicing Sugar Cane

Juicing sugar cane is actually quite difficult. It’s hard to believe how tough the stems are under pressure, and it takes a literal ton (or more) of torque to pull off. I tried chopping up sugar cane into pieces and feeding it through my Champion juicer without luck. It choked the machine, despite how incredibly tough that thing is. You really need a machine dedicated to juicing cane.

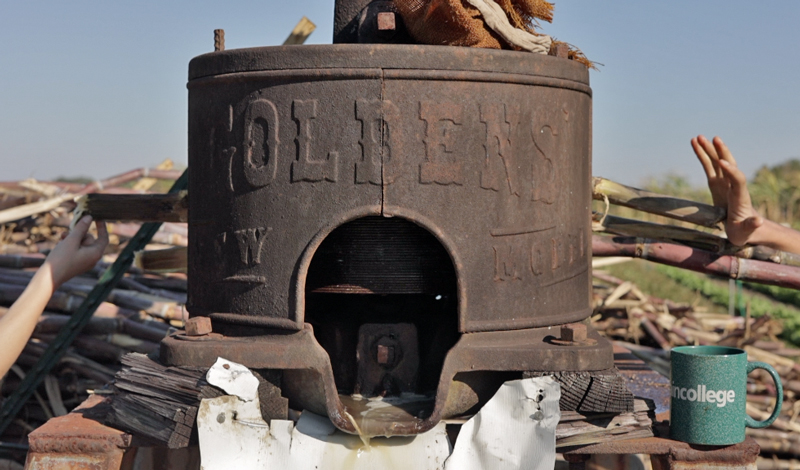

Marcus uses an antique Golden’s Cane Mill he salvaged for a good price from an organization that had been using it as a yard decoration for years.

You can see the size of the tree trunk attached to the sugar cane mill’s drive shaft in this photo I took at sunset:

In conversation, he told me the crushing power of that machine is incredible.

“Imagine a long-handled wrench and how much more force you get on a bolt,” he said. “That’s a massive amount of torque.”

He uses a small Sears yard tractor to pull the post around the mill. You can see it on the left in the image above.

Three canes at a time can be crushed by the mill, but no more. Their juice is directed down through cloth filters and into buckets, which, when filled are poured through a second cloth filter, then poured into the boiling kettle.

Juicing the cane is really the hardest part of this entire process. Once it’s juiced, it’s time for the boil.

Boiling Down Cane Syrup

Marcus boils his syrup in a 90-gallon cast iron pot. He laments not having a proper, wide syruping kettle, but uses what he has.

The actual boiling takes five or more hours. The goal is to evaporate away the water and thicken the sugar cane juice into delicious and shelf-stable syrup. A wider kettle allows for more evaporative surface.

As the syrup boils, scum is skimmed off the top.

After hours of boiling, the juice has thickened into rich amber syrup.

The syrup crew, in this case Joshua Ussery, checks the temperature regularly. As the water leaves, the temps go up from 212, and when they hit a certain point, the syrup is judged to be finished. My guess on the point they pulled this syrup is in the upper 220’s. Other signs of the syrup being finished is the “clouding” of the boil and the bubble size, and when a “sheet” of syrup falls from an overturned dipper, instead of in individual drops.

At the proper thickness, the fire is rapidly pulled and the syrup is bottled in Mason jars for later sale.

It’s an all-day event, and is rather like a big family party at Marcus’ place, instead of a work day. It certainly takes a lot of crushing and a lot of stirring, but there is a joy in the process when shared with friends and family.

And the results are certainly sweet.

Thanks for reading – I hope you enjoy the little documentary as well.

5 comments

Great cinematography David and crew. It was a pleasure to watch.

Thank you for sharing this syrup making process I wonder if this is a similar way to make the sugar as well. Thank you for the great information I did try to get store bought cane stalks and tried it on my home juicer it was super hard after to clean and it also did not work for me, hopefully there are other affordable cane juicers out there here in Canada fingers crossed.

I also noticed that the juicing seemed to be the only step that would be really difficult to do at a backyard scale. I found myself wondering how they got the juice out of cane 200 years ago? Did they use big presses powered by animals? I’ve seen videos of olives being juiced in a similar way in the Mediterranean, with a big stone mill pulled by draft horses. But then sugar cane is a lot harder and denser than olives, so I suspect that would not be enough force. I’m always looking for the low-tech option, if only to have an idea of how to make processes EMP-proof (or even just grid-failure proof). So my constant question with things like this is, how do the Amish do it?

On that same note, do you know how one would get from sugar syrup to granular sugar? Surely this does not require industrial processing, as people were processing sugarcane into granular sugar long before electricity was available. Do you just keep boiling until all the water is gone? Or would that cause the sugar to burn? How did they used to do it before industrialization?

Hi there, I’m 63 years old and yes they used a mule or donkey attached to a long pole going in circles to grind the cane. My father took the skimming and made rum from that. There a small town in Lumpkin, Georgia called westville that still do things like that. I explore anyone to visit because it is exciting to see how they did things back in the 1850’s

Loved this, thank you for sharing. Wondering how much syrup is yielded from 90 gallons of juice? Or.. can you tell me how much juice is needed to get x gallons of syrup? Thank you!

Comments are closed.